Description

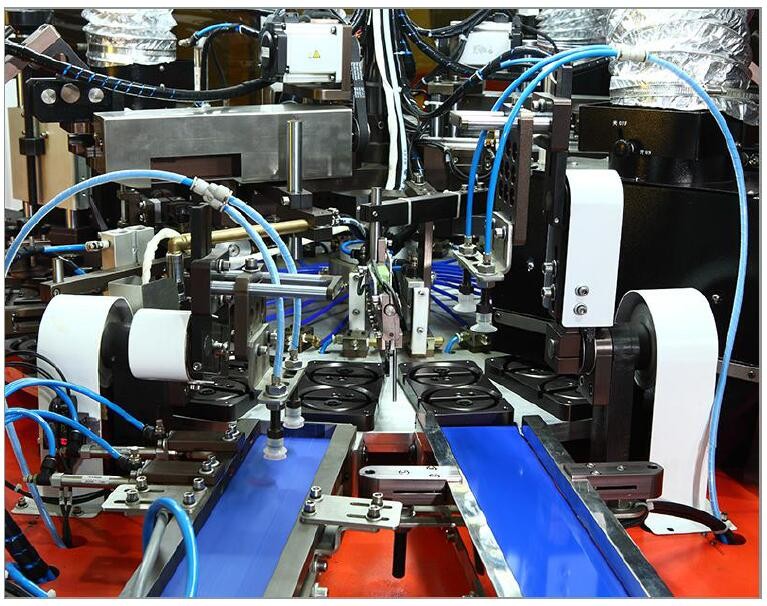

The HY-R324 is a fully automatic UV screen printing machine designed for flat surfaces that offers increased productivity and unrivalled value, available print dressing cases, stationery rulers, flat pens, etc. Our HY-R324 is driven by a SANKYO rotary positioning drive system and features a SITI main drive motor with a barrel cam.

Features of 3 Color Automatic Flat Bed Screen Printing Machine

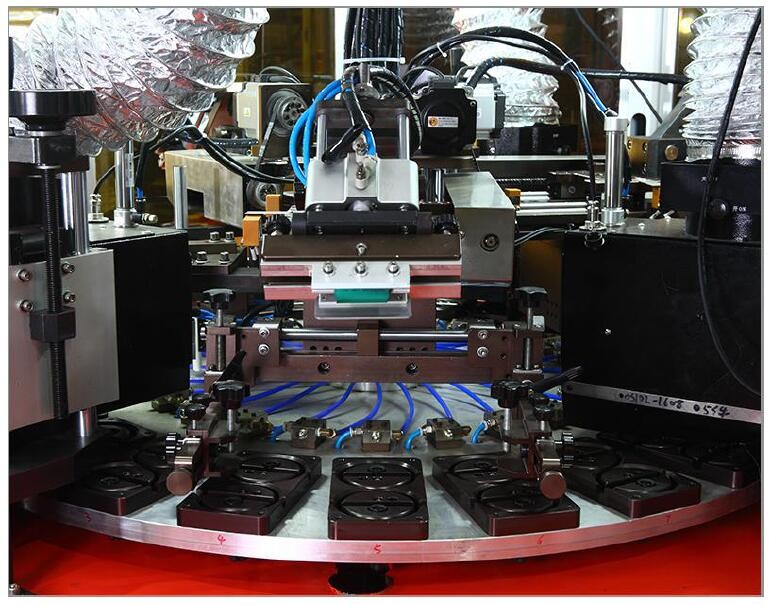

High precision mechanical rotary indexer (24 stations)

OMRON PLC controlled with touch screen

Mechanically synchronized print heads for precise printing results

Automatic loading and unloading system

Quick and easy set-up and change-overs

Motor controlled optical pre-registration device

Adjustable squeegee angle and height

Up to 110 x 90mm (4.33” x 3.54”) print area

HANOVIA brand UV Curing units (US Made)

Equipped with interlocking safety doors

Printing speeds up to 45ppm

Features of 3 Color Automatic Flat Bed Screen Printing Machine

High precision mechanical rotary indexer (24 stations)

OMRON PLC controlled with touch screen

Mechanically synchronized print heads for precise printing results

Automatic loading and unloading system

Quick and easy set-up and change-overs

Motor controlled optical pre-registration device

Adjustable squeegee angle and height

Up to 110 x 90mm (4.33” x 3.54”) print area

HANOVIA brand UV Curing units (US Made)

Equipped with interlocking safety doors

Printing speeds up to 45ppm

Three Color Automatic Flat Bed Screen Printing Machine PrinterThe HY-R324 is a fully automatic UV screen printing machine designed for flat surfaces that offers increased productivity and unrivalled value, available print dressing cases, stationery rulers, flat pens, etc. Our HY-R324 is driven by a SANKYO rotary positioning drive system and features a SITI main drive motor with a barrel cam.

Specification

| Model NO.: | HY-R324 |

| Print product size: | L160 x W160 x H100 mm |

| Max. print area: | L110 x W90 mm |

| Max. printing speed: | 45 pcs/min |

| Drive: | Mechanical driven |

| Flame treating system: | 1 unit |

| Print head: | 3 units |

| Stations: | 24 stations |

| UV system: | 3 units electronic UV system, 5KW per each |

| Deionizing device: | 1 unit |

| Motor: | ITALY SITI |

| Control system: | OMRON PLC & Touch Screen |

| Pneumatic parts: | Japan SMC |

| Electrical supply: | 380V/480V 3phase 50Hz/60Hz |

| Air requirement: | 6-8bar |

| Power consumption: | 10 KW |

| Machine dimension: | L4950 x W3150 x H2350 mm |

| Weight: |

1500 KG |