Description

1.Labeling Accuracy: ±1mm

2.Labeling Speed: 0~90 pcs/min

3.Applicable Product Size: No requirement (depends on conveyor parameters);

4.Applicable Label Size:

Length: 10mm~300mm;

Width (including backing paper width): 10mm~150mm;

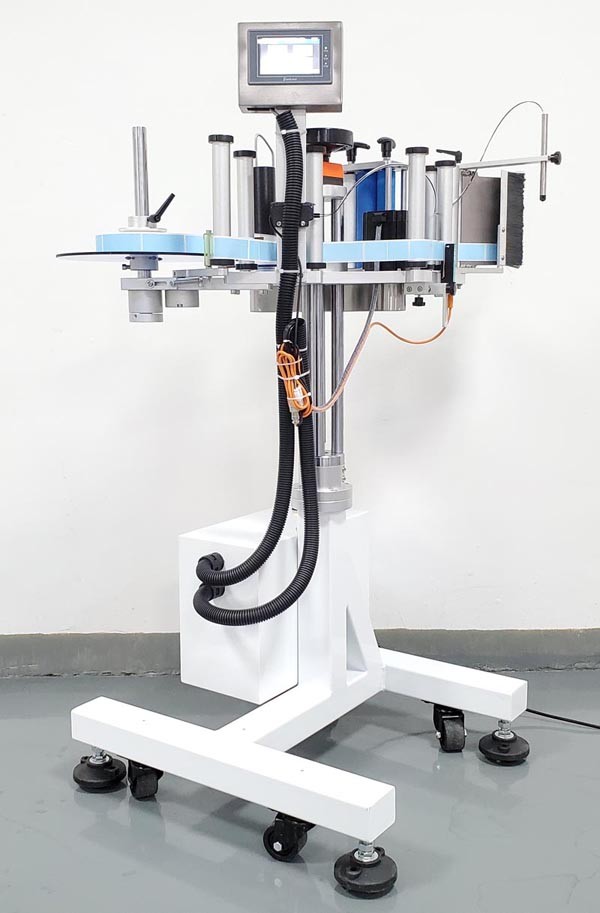

5.Machine Dimensions: Approx. 780mm×630mm×1260mm (Length×Width×Height); Height can be customized;

6.Applicable Power Supply: 220V/110V 50/60 HZ;

7.Overall Machine Weight: Approx. 90Kg;

8. Applicable Label Inner Diameter: Ø76mm; Applicable Label Outer Diameter: Ø300mm

Basic Applications

Suitable for use in workshop assembly lines for side labeling of products, enabling online labeling. When paired with an inkjet printer, labeling and coding can be completed in one step.

Applications

Applicable Labels: Self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

Operation Process: Product Feed (connected to the production line) → Product Conveying → Product Detection (or Receiving External Signals) → Labeling → Labeling Application.

Features

Simple to install, can be directly installed on production lines and packaging machines, independently or in conjunction with other systems to achieve automatic labeling and unmanned labeling production;

Flexible application, can be configured with different labeling mechanisms to apply labels to both flat and uneven surfaces;

Easy adjustment, the adjustment structure uses a single-bar structure, the label head is flexibly adjustable in six degrees of freedom (x/y/z), flexibly matching different production lines;

High labeling accuracy, the label tape winding and correction mechanism prevents label deviation, and the microstepping motor drives the label dispensing, ensuring accurate label positioning;

Intelligent control, automatic photoelectric tracking, with no-label-no-item capability to prevent missed labeling and label waste;

Touchscreen operation interface with full Chinese annotations and comprehensive fault prompts, various parameters are simple and quick to adjust, and operation is convenient;

Applicable Products: Can be integrated with pillow packaging machines, automated production lines, printing machines, etc., for online labeling.

Application Industries: Widely used in packaging, food, toys, daily chemicals, electronics, pharmaceuticals, and other industries.

Application Examples: Labeling before film bag forming, assembly line labeling, etc.

Working Process

Core Working Principle: Sensors detect the passing of a product and transmit a signal to the labeling control system. At the appropriate position, the control system controls the motor to deliver the label and attach it to the product's labeling location. As the product flows past the labeling brush, the label is firmly applied, completing the labeling process for one product.

Features

Simple to install, can be directly mounted on production lines and packaging machines, independently or in conjunction with other systems for automatic labeling and unmanned labeling production;

Flexible application, can be configured with different labeling mechanisms to label both flat and uneven surfaces;

Easy adjustment, the adjustment structure uses a single-bar design, the label head is flexibly adjustable in six degrees of freedom (x/y/z), flexibly matching different production lines;

High labeling accuracy, the label tape winding correction mechanism prevents label deviation, and the microstepping motor drives label dispensing, ensuring accurate label positioning;

Intelligent control, automatic photoelectric tracking, no-labeling-no-item function, preventing missed labeling and label waste;

Touchscreen operation interface with full Chinese annotations and comprehensive fault prompts, various parameters are easy and quick to adjust, and operation is convenient;

High stability, using a Panasonic PLC + touchscreen display + microstepping motor + fiber optic sensor control system, precise control, supports long-term operation;

Optional functions:

① Thermal coding/inkjet coding function;

② Movable bracket;

③ Other functions (customizable according to customer requirements)