Description

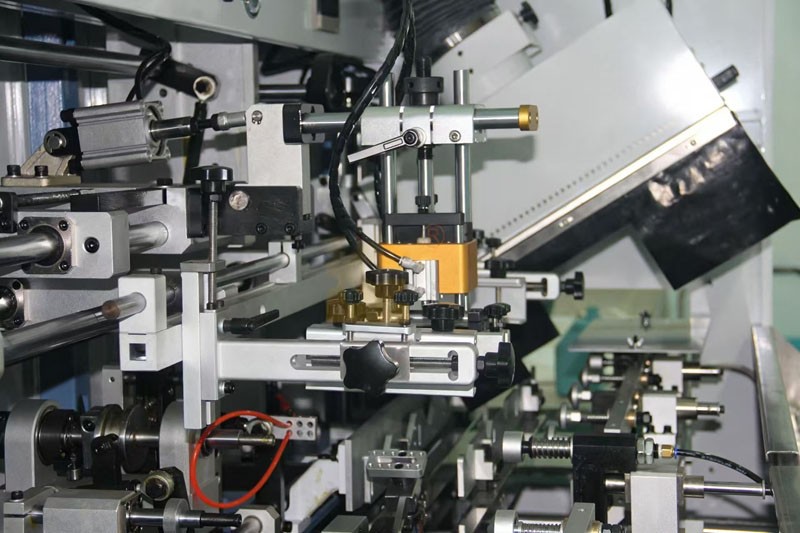

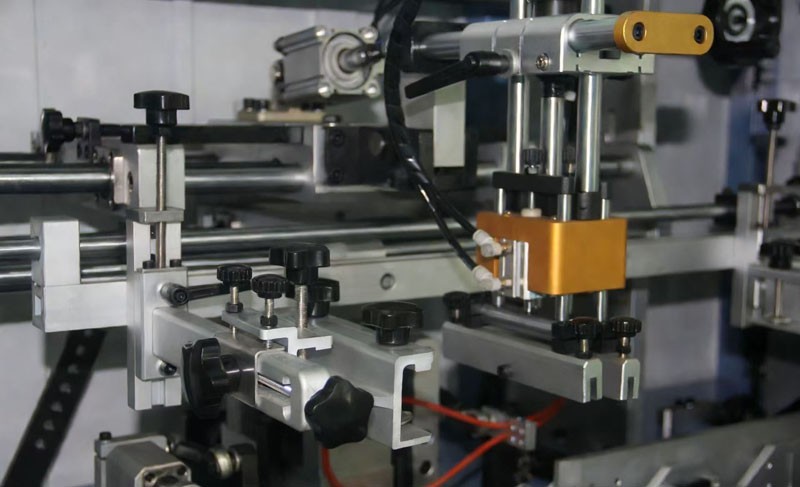

EC-120AL-1 it is a full mechanical conveyer, With the touching control panel operation, easy to operate the machine. Fast adjustment, easy operation. Fast printing, speed: 4000pcs/hr

The following is the machine main parts

1. MAIN MOTOR: SITI(Italy)

2. PLC: Omron(Japan)

3. SENSOR: Optex(Japan)

4. TOUCH SCREEN: Proface(Japan)

5. Switch: Schneider(France)

6. (CONTACTOR):(Schneider)(France)

7.(RELAY): (Idec)(Japan)

8. (INVERTER): Omron(Japan)

9. (UV CURING)(Primarc)Britain

10. (Cylinder):Festo(Germany)

Product Information:

1.The machine is specialized design for printing the round or oval bottles, with easy operation and stable.

2. Feeding machine can load product to the screen printing machine automatically..fully automatic feeding, flame treatment, UV screen printing and UV curing.

3. It is a mechanical conveyer ,With touching control panel operation , easy to operate the machine. Fast adjustment, easy operation. Fast printing,speed:4000pc/hr.

4. Fully automatic,It will alarm when the machine without product loading and no printing without product. it can save energy.

5. All components and control system are from Germany and Japan, guarantee the quality of the print.

The following is the machine main parts

1. MAIN MOTOR: SITI(Italy)

2. PLC: Omron(Japan)

3. SENSOR: Optex(Japan)

4. TOUCH SCREEN: Proface(Japan)

5. Switch: Schneider(France)

6. (CONTACTOR):(Schneider)(France)

7.(RELAY): (Idec)(Japan)

8. (INVERTER): Omron(Japan)

9. (UV CURING)(Primarc)Britain

10. (Cylinder):Festo(Germany)

Product Information:

1.The machine is specialized design for printing the round or oval bottles, with easy operation and stable.

2. Feeding machine can load product to the screen printing machine automatically..fully automatic feeding, flame treatment, UV screen printing and UV curing.

3. It is a mechanical conveyer ,With touching control panel operation , easy to operate the machine. Fast adjustment, easy operation. Fast printing,speed:4000pc/hr.

4. Fully automatic,It will alarm when the machine without product loading and no printing without product. it can save energy.

5. All components and control system are from Germany and Japan, guarantee the quality of the print.

6. It is suitable for print round/oval product printing such as the cosmetic bottles, drink bottles, cans ect

| Specification | |||

| Subject surface | Oval | Round | |

| Max speed | 4000pcs/hr | 3600pcs/hr | |

| Max print length | 120mm | 270mm | |

| Max print wide | 250mm | 250mm | |

| The size of print | diameter:Φ25-Φ260mm | diameter:Φ25-100mm | |

| Length :60-270mm | Length :60-270mm | ||

| The power of UV lamp | 4Kw/unit | ||

| UV air draft power | 0.2KW | ||

|

reduction

gearbox Conveyer proportion

|

01:07.5 | ||

| Single motor power | 0.75KW | ||

|

The

power ofbottle liftervacuum motor

|

0.5KW | ||

| Vacuum supply | 500 mmAq | ||

| Flame treatment fuel | LPG | ||

| air supply | 6Bar | ||

| Air consumption | 400Liter/Min | ||

| Power supply | AC380V 3Phase 50Hz | ||

| Package dimensions: | 267*146*216CM | ||

| 219*80*172CM | |||

| Package weight: | 1600KG | ||