Description

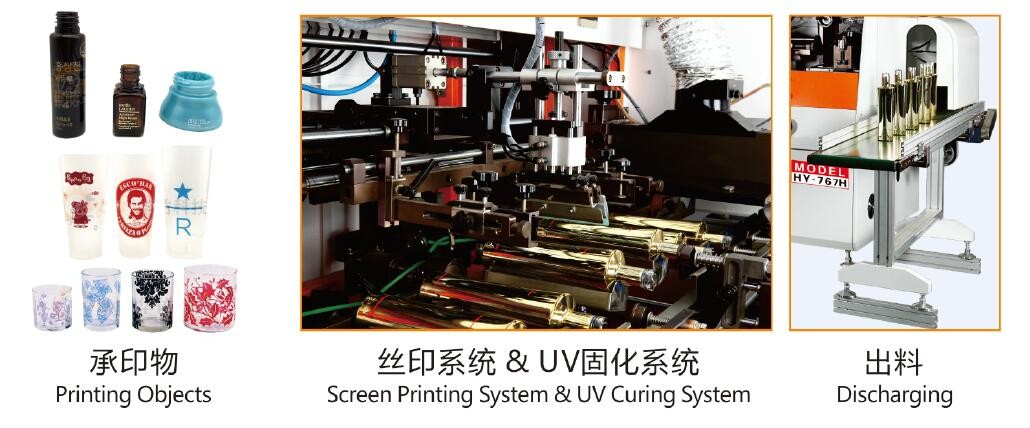

HY-767H is a heightened and widened, 2 colors silk screen, to meet the special needs of customers' production lines.

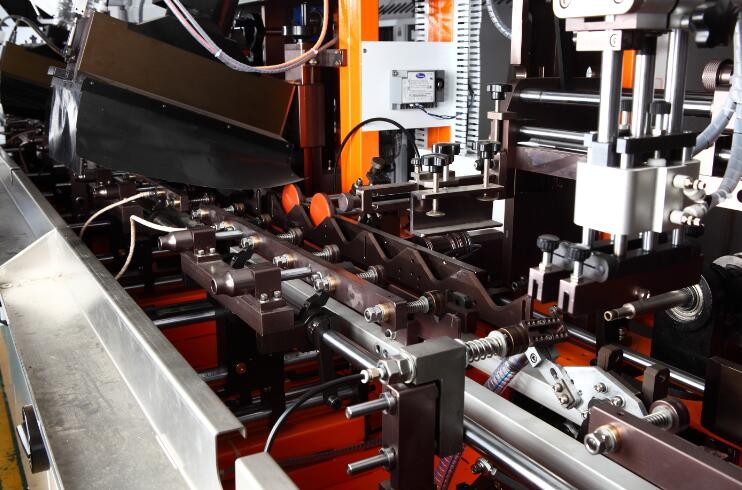

Suitable for round, oval, square and other objects; entire machine with reasonable structure, convenient debugging and stable operation.

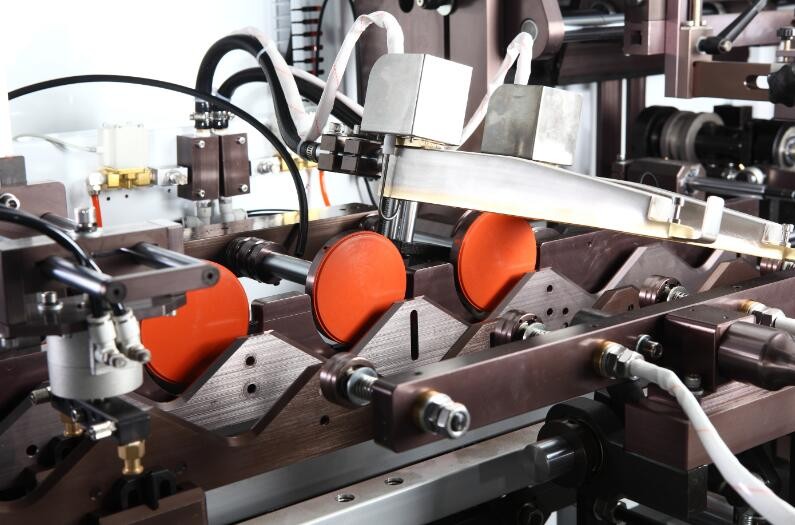

Integrate multiple functions such as synchronous automatic feeding, automatic lifting printing, mercury lamp/high-intensity LED/ultraviolet curing, etc., to achieve high-efficiency printing work.

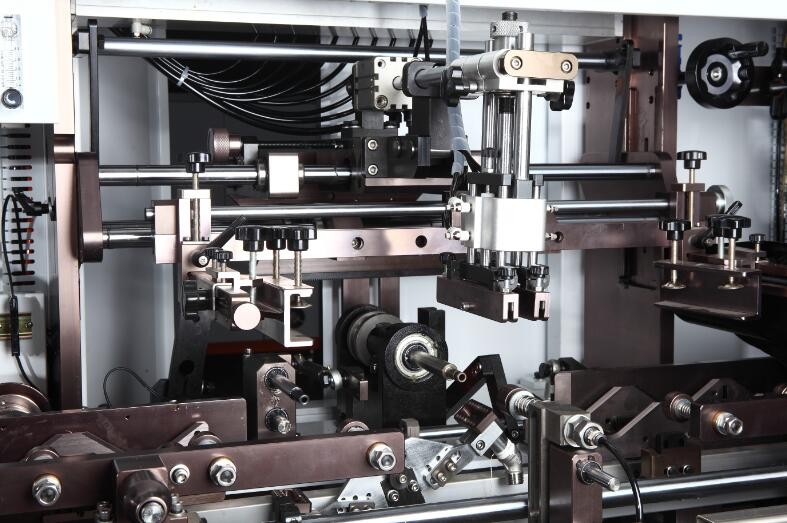

The electronic components and control system of the printer are imported from well-known German and Japanese brands to ensure higher quality and huger quantity of products.

Through the international famous brand touch screen PLC, it is easy to realize the man-machine dialogue, and the operation is more convenient.

With the function of pre-alignment of bottles, the printing process is more efficient and accurate.

Realize automatic monitoring functions such as “no object no printing” and low air pressure alarm through electronic sensors.

The principle of the whole machine is mechanical synchronization, which can easily realize a fully automated one-stop production line, freely combine single-color, double-color or even multi-color printing.

Customizable automatic combined production line: CCD vision inspection, automatic labeling, automatic hot stamping, etc., to meet the high standards of various printing and packaging processes.

Main Specifications of One Color Automatic UV Silk Screen Cylindrical Printing Machine HY-767H

Model NO.:

HY-767H

Round container size:

Diameter: φ10-100mm, Height: 30-260mm

Round container max. print area:

L 260 x W220mm

Oval container size:

R: 10-250mm, Height: 30-260mm

Oval container max. print area:

L 120 x W220mm

Drive:

Mechanical Driven

Control system:

OMRON PLC & Touch Screen

Max. printing capacity:

70 pcs/min

Registration tolerance:

+/- 0.2 mm

Infeed conveyor:

1 unit, length: 2 meters

Deionizing device:

1 unit

Flame treating system:

1 unit, LP gas

Motor:

ITALY MOTOVARIO

Print head:

1 unit

UV system:

1 unit intelligent UV system, 5KW per each

Outfeed conveyor:

1 unit, Length: 2 meters

Frequency Converter:

OMRON

Pneumatic parts:

FESTO or SMC

Electrical:

380V 3phase 50Hz

Air requirement:

5-7 bar

Air consumption:

85 liter/ minute max. (per color)

Power consumption:

5.4 KW/color x 1

Machine size(LxWxH):

Main machine:5000x2500x2000mm

Weight:

3000 KG