Description

Typical Features of Automatic Round Hot Stamping Machine HY-106T

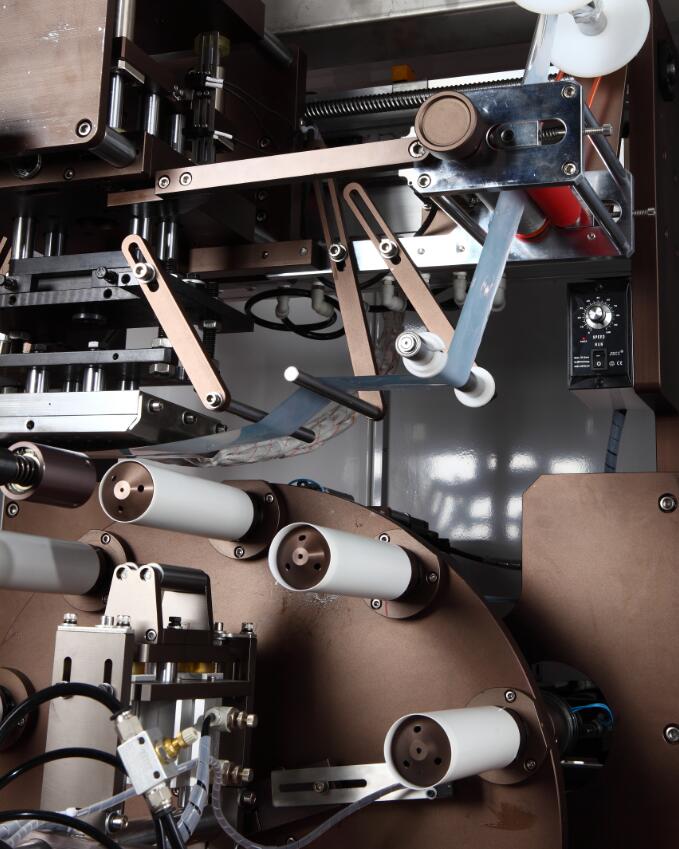

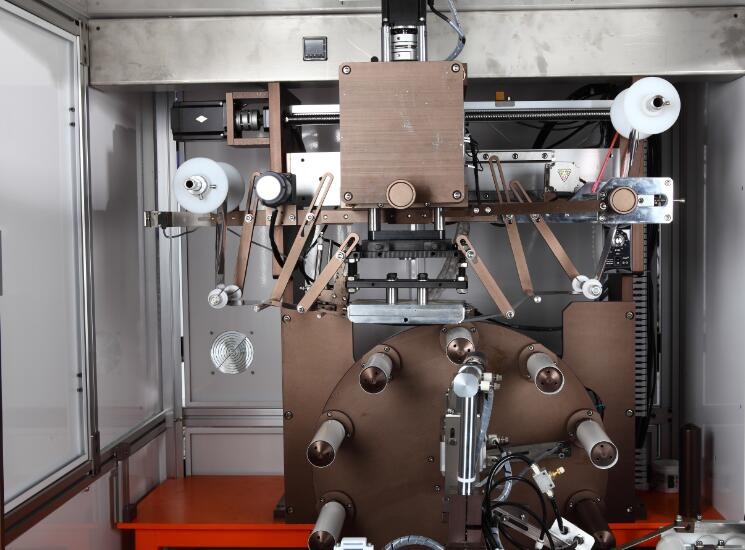

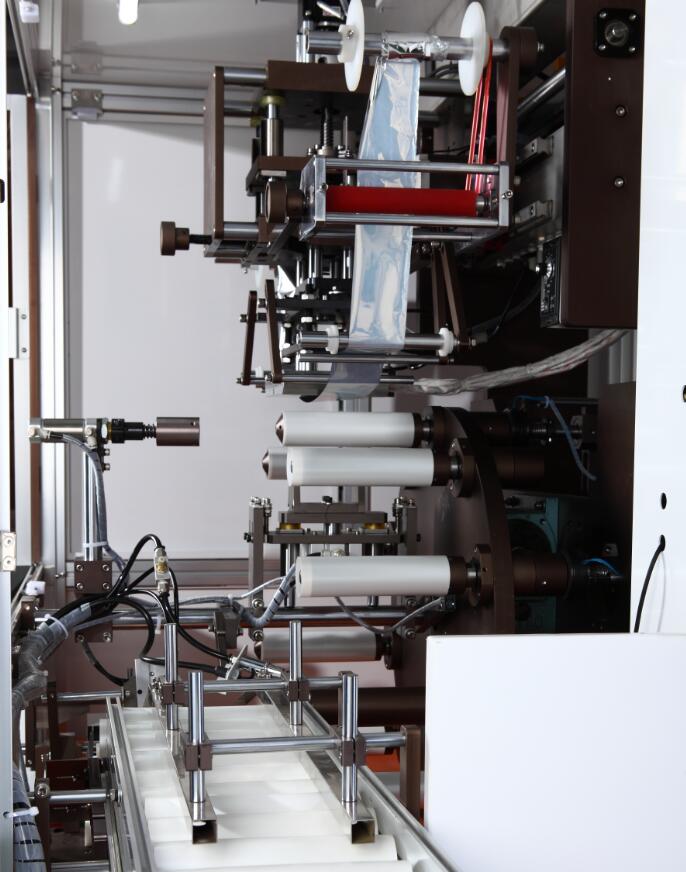

The automatic hot stamping machine is the automatic hot stamping equipment latest developed by our company, which is mainly used for hot stamping of patterns and text on the surface of cylindrical plastic bottles, bottle caps and other rotating bodies. The head can be adjusted in angle and forward & backward displacement. Temperature, speed, hot stamping length, the force of paper delivery and feeding etc. are adjustable.

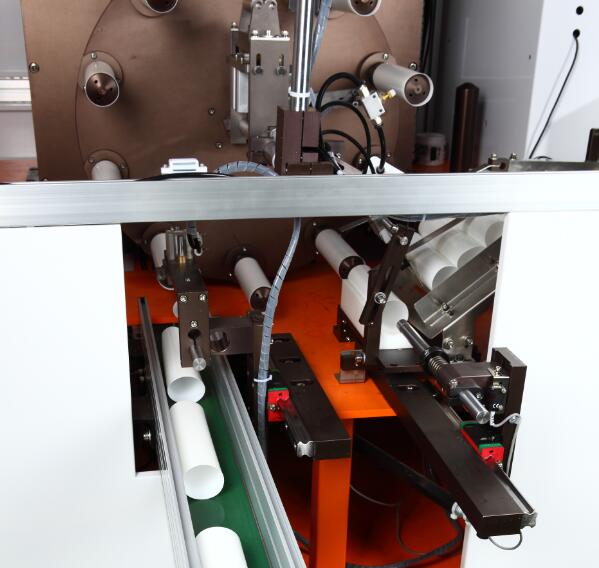

Suitable for hot stamping on: various round bottle caps, soft tubes (containers of cosmetics, medicine and food etc.).

The control system of the whole machine adopts Japanese OMRON PLC and touch screen, to ensure the machine to operate easily and run smoothly & reliably.

Fully automatic loading system and unloading manipulator device ensure the continuity and stability of printing, and avoid the scratches on the surface of the printing material as much as possible during the printing process, more ensure the safe operation of the operator.

Due to specialized electronic sensors, it achieves automatic monitoring functions such as "no object, no hot stamping", and automatic alarm when low air pressure or lack of gold foil etc.

"No object, no hot stamping" function can ensure the continuity and material-saving of the machine's high speed hot stamping.

The roll paper is controlled by servo motor. By setting the corresponding roll paper length to reduce the waste of gold foil; for hot stamping on small colored patterns, the paper length can be controlled quickly and accurately, thereby greatly increasing the speed of hot stamping.

Main Specifications of Automatic Round Hot Stamping Machine HY-106T

Model NO.:

HY-106T

Print product size (DiameterxLength):

Ø:10mm-40mm, H:20mm-150mm

Max. print area:

40x100mm

Max. printing speed:

50-60 pcs/min

Registration tolerance:

+/- 0.2mm

Drive:

Mechanical driven

Control system:

OMRON PLC & Touch Screen

Stations:

6 stations

Deionizing device:

1 unit

Print head:

1 unit

Motor:

ITALY SITI

Pneumatic parts:

Japan SMC

Photoelectric Sensor:

Japan Keyence

Frequency Converter:

Japan OMRON

Indexer

Japan SANKYO

Electrical Supply:

380V 3phase 50Hz

Air requirement:

6-8 bar

Power consumption:

3.2 KW

Machine Dimension (LxWxH):

2700x2100x2100mm

Weight:

1000 KG